Simple diy painted plates.

Diy bullet proof ceramic plates.

Shooting the diy plate armor.

The second video is couch potato mike and i shooting the ballistic plate.

In this video i show you the complete process i use to make a curved ballistic plate insert that could be used in a plate carrier.

This thing is heavy.

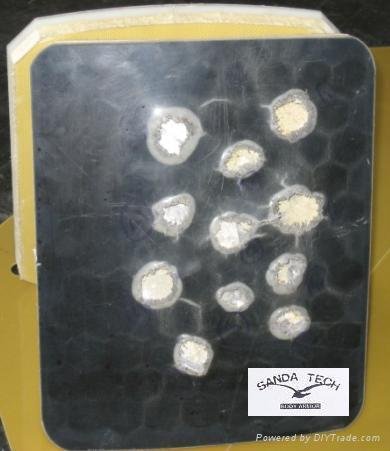

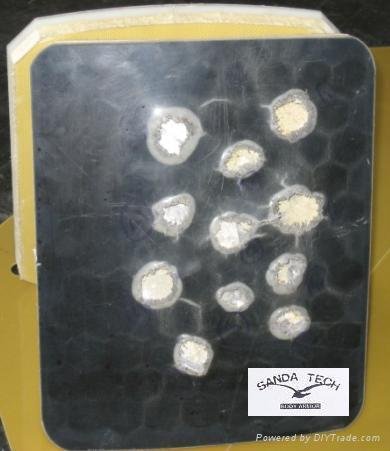

No bullets got through the plate.

Level iv multi hit rifle ceramic body armor plates use a monolithic piece of ceramic that can produce small cracks throughout the body armor plate when hit by an m2ap round.

The cost for this was around 30.

Cut the fiberglass into 8 by 96 inch wide strips on a board covered with saran wrap.

I used a steel i beam piece a ceramic floor tile duck tape and a can of plastidip.

Now that you know how to build a diy ballistics plate body armor it s time to destroy it.

And tough as a hell.

You start with plain white ceramic plates and use gold markers and gold star stickers to embellish them.

These small cracks can drastically decrease the integrity of the plate and reduce its chances of defeating multiple rounds.

The ceramic tile was demolished.

For personal protec tion or for helicopters silicon carbide materials may be used.

For the 20 30 bucks i spent building this diy body armor it was money well spent.

In my own testing i was able to shoot a 5 56mm rifle round through a ballistic steel plate which would tend to invalidate it for body armor.

As a commercial domestic bullet proof system manufacturer jim richards isn t all that impressed with ceramics.

Beside these qualities other ceramic materials have also been considered and were examined intensive ly for the purpose of ballistic.

Ceramic plates fail to offer the weight advantages and ease of handling fabricators and installers enjoy with fiberglass based bullet proof panels.

Shooting the diy plate armor the second video is couch potato mike and i shooting the ballistic plate.

Allow it to cure for three days.

Only when an extremely low weight is required e g.

Once you heat these in the oven to set in the design they will stay designed for years and you can do them in various different colors if you want just use different colored markers.

Mix polyresin and the hardener and pour it over the ceramic tile plate and sheet metal ensuring that the sheet metal is placed on the bottom of the mold.